OUTDOOR LED EDGELIT LIGHT PANELS

April 2014

Sign: MAG Assembly

MAG Assembly Ltd announces their new range of IP67 rated outdoor

edgelit light panels display stands. There are 3 models for wall mount,

and free-standing in single and double. All three have an illuminated

display face of 1200x1800mm portrait.

These units are fully weatherproofed

by using full-face door weatherstrip rubber seals, and two recessed

camlocks at the bottom to pull the door up tightly against the seals.

Another main feature is the hingeless front door allowing the door to

be quickly and easily changed by one person if a damaged door needs

to be replaced. Doors are hinged at the top and open to 36º allowing

easy access to the top of the poster, and are supported by gas struts

so they don’t get caught by the wind, and also to provide for soft opening

and closing. Top hinged door means that there is no water pooling at

the top common with most conventional side-hinged doors.

The edgelit

light panels used are the exact same Vivacity edgelit panel technology

used in the edgelit poster frames giving a bright 2300 Lux of illumination

evenly across the entire display face without any shadowing in the centre,

and are illuminated on 2 edges only using half the power of conventional

panels and generating virtually no heat.

Specifications and Features:

- Single and double-sided models

- IP67 weatherproofing

- No ventilation required and no condensation issues

- Top hinging door without hinges to prevent water pooling and ingress

- Door opening from the bottom and swings up 36°

- 2 gas struts for door support, wind-resistance and soft opening/closing

- 6mm Grade A toughened glass door panel

- Optional Graffiti guard coating

- Poster size 1200x1800mm

- R-Clip poster mounting system for fast poster changeouts

- Vivacity 12VDC edgelit light panel 2300 Lux illumination

- Power draw only 0.21 Amps @ 240V (single-sided)

- Powdercoated or 2-Pak spray painted to any colour specification

- Free-standing models include solid galvanised steel spigot base for solid footing

- Overall dimensions: 1317x1919x100mm (wall mount)

- 1317x2020x100mm (free-standing single-sided)

- 1317x2020x185mm (free-standing double-sided)

CROMBIE LOCKWOOD

November 2013

Client: Onform Signs Ltd

– Jared Percival

In December 2012 MAG was contracted by Jared Percival at Onform Signs

to design, prototype and manufacture new sky signage for Combie Lockwood’s

new Queen Street head office building in Auckland. The signage consisted

of 3 sets of 1200-1600mm illuminated Ali channel letters, with opal

faces and rolled retaining rings to ensure secure fixing of the faces

in typical maximum wind loadings. The letters were painted 3 different

colours to match the retaining rings to the faces and the sides of the

letters to the building façade. Jared applied translucent vinyl for

the green letters before installing them on the top of this 24 storey

building in November 2013.

Some of the extra challenges on this job

were that there was only lift access to the roof so all the signage

had to be fabricated in modular component to fit in the lifts. The signage

also required extra engineered mounting framework to bridge the negative

detail gaps in the building façade.

Another big challenge is to have

a high level of communication between all parties involved including

the client, manufacturer, local authorities, engineers, installation

contractors, building managers, electricians, to ensure that everything

comes together on the top of the roof without any complications or problems,

as when you are hanging over the side of a 20 storey building it’s critical

that everything fits first time to avoid delays and extra costs.

AUCKLAND VETERINARY CENTRE

November 2013

November 2013

Sign: Auckland Veterinary

Centre

Client: Signwise Auckland Ltd – Dave Woodfield

In August

2013 Dave Woodfield at Signwise asked MAG to quote on a new digital

LED sign for a customer who had seen the one at Murphy’s Law pub in

Drury and wanted to do something similar to promote their busy Veterinary

practice. Having known about MAG’s previous experience in digital LED

signs and our alliance with Yesco Electronics, Dave’s customer wanted

to have a larger display that was more functional than just displaying

a line of scrolling text, and MAG selected a computer controlled 20mm

pitch resolution display in 3 colours. This 2300x700mm programmable

display gives the customer the ability to display multiple lines as

one entity, or two separate lines of text that can be programmed for

separate effects, with a wide range of different special effects that

can be applied, as well as a full graphics capability to display images.

This sign has a Wifi connection to a computer inside enabling the customer

to make changes on the fly and look out the window to see what it looks

like on the sign without having to leave their seat! The final design

is a stunning looking sign that is visible at a long distance and is

a credit to the Signwise team.

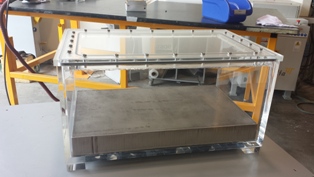

MAG ASSEMBLY HELPS WORLDWIDE LAUNCH OF XBOX ONE

November 2013

Client: Pead PR – Matt

Young

New Zealand Herald: First Xbox hurdle - survive the shark tank

The Xbox One was launched worldwide in NZ on 22 November 2013, and

in the week leading up to the launch the world’s first Xbox One unit

was unveiled a week beforehand at the bottom of the 3.5m deep shark

tank at Kelly Tarltons in Auckland. MAG Assembly had previously made

many acrylic pieces for Kelly Tarltons, so they recommended MAG to build

a display box suitable for the job. The brief to MAG was to build a

one-off waterproof acrylic box with an easily removable lid that was

to sit in salt water at 3.5 meters depth for a week. The box had to

be guaranteed to stay upright on the bottom even if knocked by a shark,

and guaranteed not to leak as the Xbox had to be removed on-camera and

given away to the first NZ customer at the launch of the Xbox at the

Vodafone Music Awards. MAG designed and built a 15mm acrylic box with

mitered interlocking edges to relieve any pressure on the acrylic glue,

redundant seals, 24 non-penetrating bolts, and a 60mm thick steel plate

to help keep it upright and securely on the bottom. Small refinements

such as acrylic feet allowed the 80Kg box to be more easily picked up

and put down without trapping fingers, and a slightly oversized lid

provided for easier removal.

AIG

October 2013

Sign: AIG

Client:

Onform Signs Ltd – Jared Percival

In August 2012 we were

commissioned by Jared at Onform to fabricate the new sky-signage

logo for AIG for the Shortland Street Head Office. These were fabricated

as aluminium channel letters painted metallic silver with an Opal

face LED illuminated mounted onto an ACM clad sub-frame. There were

4 sets of these letters installed on the top of each side of the

building in September 2012. In October we were commissioned to add

the rectangular border around the edges of the backing panels in

line with AIG’s corporate image.

TAKANINI VILLAGE

October 2013

October 2013

Sign: Takanini Village

Client: Signs Advertising Ltd - Bryan

The new Takanini Village

shopping centre still being completed in Walters Road needed a large

pylon with real street presence that was visible from the Great South

Road intersection. The customer supplied an overall concept of what

they wanted and MAG was asked to get involved with the design of the

pylon to achieve the look that the customer wanted whist also allowing

for the best material yields and an easy construction design that resulted

in a very cost effective 10m high by 2m wide pylon, fully illuminated

with nearly 1562 Axle9 LED modules giving nearly 3kW of illumination

for less than 8 Amps of mains power. Other requirements were integral

individual retailer graphic panels that were able to be quickly and

easily changed out, and separate UV signs for the shopping centre in

keeping with the same look and feel of the pylon design. The pylon was

further extended by installing it onto an 1800mm high concrete plinth

giving an overall height of nearly 12m, and this sign is easily seen

from the port side of planes on approach to Auckland Airport.

MAG ACQUIRES NZ AGENCY FOR VIVACITY

April 2013

April 2013

In April 2013 MAG Assembly was proud to be appointed NZ Agent for the

Melbourne based Vivacity edge-lit light panels.

In April 2013 MAG Assembly was proud to be appointed NZ Agent for the

Melbourne based Vivacity edge-lit light panels.

The advantages of

an edge-lit light panel over a standard lightbox are that it is cheaper,

less bulky, with a slim profile of no more than 20mm out from the mounting

surface for a more discreet presence or where an illuminated ‘poster

frame’ look is required, or where depth of the sign is an issue.

The main disadvantage is that most edge-lit light panel faces won’t

illuminate evenly if the height of the panel is greater than 600mm,

which effectively limits the panel to a maximum A2 size. Panels larger

than this will have a dark shadow in the middle of the panel where the

light will not reach.

Vivacity light panels use a South Korean made light panel that uses

a patented diamond-etch technique to create a light-guide plate only

3mm thick that will evenly illuminate across the entire panel up to

2 meters high.

Available in two thicknesses of 16mm or 20mm depending on the face size,

Vivacity light panels only need illuminating from the top and bottom

edges using top-of-the-line Samsung LED’s, providing a more cost-effective

light panel than most competitive options, that is also thinner, brighter,

has no edge hot-spots, no centre shadowing, is more durable and energy

efficient, and doesn’t run hot. In addition, there are also 3 different

brightness levels available using different LED pitch spacing.

The light panels include an integrated snap-loading frame for fast and

easy change out of graphic content. Available ex-stock in common sizes

from A3 to A0, and on indent in any custom size up to 6mx2m with a MOQ

of 10 units.

These edge-lit light panels are also the perfect retrofit to the standard

1200x600mm office fluorescent lighting troffer packs, providing an increased

and more even lighting levels in warm or cool white, less eye-strain

and fatigue, reduced maintenance requirements and huge power savings!

For increased ambience, a high resolution colour graphic can be inserted

in the integrated snap frame, to create for example, a realistic and

aesthetic image of any simulated external view from out of a skylight.

Cut through the competition and give your client the ‘edge’ with the

World’s most advanced edge-lit panel technology.

MAG ACQUIRES NZ AGENCY FOR VIVACITY E-PAPER POP MOTION DISPLAYS

April 2013

In April 2013 MAG Assembly was proud to be appointed NZ Agent

for the Melbourne based Vivacity E-Paper POP motion displays.

Vivacity motion displays provides the new generation of POS displays

- Electronic Paper Displays.

With animated messages and eye-popping

colour graphics the displays significantly increase customer awareness

and sales at point of purchase. The displays are thin, light-weight,

and powered by batteries, enabling easy mounting and integration

anywhere and on anything.

With 70-80% of the purchasing decisions

made in the store, the most critical place to grab attention and

affect purchasing decisions is in front of the actual product. Traditional

paper based point-of-sale messages are not sufficient in today’s

retail environment to draw customer attention and differentiate

a product or brand from competitors.

With Vivacity motion display

E-Paper, your POS signage will never be the same again.

MAG ACQUIRES NEW WEEKE VANTAGE

200/174 CNC PROCESSING CENTRE:

February 2013In February 2013 MAG took delivery of our new Weeke Vantage 200/174 CNC Processing Centre. This machine has a 4.3m x 2.25m table bed allowing us to process the largest available sheets for any job. with an accuracy of 0.025mm this router will ensure repetitive precision machining on all jobs. This is the fastest and largest CNC router in NZ (machine capability) with a 9kW spindle, end to end travel in 2.4 seconds, and can groove ACM at 30m per minute with a custom made ACM rotary saw. More that just a CNC Router, this machine does drilling, sawing and grooving and has an additional 360 degree C-axis head for true 3D processing giving it 5-axis capabilities and the ability to produce complex 3D shapes up to 100mm high. It also has a separate 2.3kW 12-bit drilling head, and can drill material whilst simultaneously routering on the main spindle.

YESCO LED BACKLIT OUTDOOR HD LCD

February 2013

MAG Assembly now has available the new line of YESCO high brightness

LED backlit outdoor High Definition LCD systems and made them bigger,

brighter and easier than ever to service. YESCO is one of the leading

US manufacturers of LED electronic outdoor billboards in the US,

and have recently installed the worlds largest HD billboard in Las

Vegas.

Video overview: Yesco Y72 Outdoor LCD Display

KEY FEATURES

• High Brightness in direct sunlight > 2000 Nits

• Custom made High Definition 1920x1080p LC display

• Brightness auto adjusts to ambient light levels and dims at night

• HD Outdoor High Temperature LCD Screen

• Air-conditioned cabinet to control extreme heat buildup in NZ

conditions

• Modular System is easily serviceable

• Low Cost Leasing Options

• Vandal-proof cabinet with scratch-resistant shatter-proof glass

• Cabinet is IP65 rated for outdoor use in the extreme NZ weather

conditions

• Screen sizes in 47", 55" and 72" single or double-sided, portrait

or landscape

• Wi-fi and CAT5 internet connection for monitoring, servicing and

online content updating

• Low power consumption - draws only 8A for 240VAC

• Average life expectancy of 7 years, however these displays are

engineered to last 10 years

The Y72 system is designed to replace free standing poster board

signs in applications ranging from bus stops, to college campuses,

to amusement parks and to sports stadiums, to name a few.

GULL PETROLEUM

November 2012

November 2012

Sign: Gull Petroleum

Ltd

Client: Xtream Signs – Matt Porteous

In early 2012 MAG

was approached by Matt Porteous at Xtream Signs to see if we could help

him with his rollout project to re-image all the Gull Service Stations

nationwide. Matt had heard that MAG was a key supplier to the Z Energy

petrol station re-branding rollout and that MAG would be the ideal partner

to manufacture new fascia panels and frames for the forecourt canopies,

various forecourt above-pump blade signs, as well as replacement new

road-front pylons. The rollout program commenced in September 2012 and

is still on-going as at June 2014, and is a very good example of how

MAG can help smaller sign companies still take on major signage projects.

MAG ASSEMBLY UPDATES AMP NZ HEAD OFFICE SKY SIGNAGE

November 2012

Sign: AMP

Client: Sign Manager Australia

Sign Manager in Australia were engaged by AMP Australia to update

all their worldwide signage to their new look logo lettering and

new 'Spark' Logo. MAG Assembly had previously built the original

signage for NZ Head Office on the top of the AMP Building downtown

Auckland in early 2007 for our client Claude Neon .Sign Manager

in Australia looked for someone in NZ with the required large scale

manufacturing expertise to make such complex sky signage, and MAG

were again contracted to build the new sign and logo for all 4 sides

of the building.

Both the new letters and the Spark logo were all hand fabricated

as channel letters and the overall sign is over 13m long and 4m

high. Whilst the AMP lettering is illuminated by MAG's bright white

Axle9 LED's, the Spark logo uses a gradient-fill blue patterns on

translucent UV vinyl applied to an Opal acrylic face and is illuminated

at night by a new type of RGB Smartpuck LED systems used on many

of the large billboards in Las Vegas. The RGB LED's are driven by

a computerised DMX controller enabling a range of illumination effects

from a simple cool-white steady illumination as currently set up

to backlight blue colours on the Spark logo, to very complex 16-million

colour dynamic animations.

Congratulations to AMP and Sign Manager on an exciting new logo

and sign that stands out from most others!

Z ENERGY ROLLOUT PROGRAM

July 2012

Sign: Z

Client: Harkess Ord

In 2011 MAG was chosen by Harkess Ord to be the principal supplier to Z Energy rollout rebranding conversion from Shell to Z Energy. MAG supplied over 15Km of service station canopy fascia, as well as canopy Z logo clip signs, and carwash fascia and signs for 310 petrol service stations and Truck Stops across NZ from November 2011 to July 2012. MAG was also a co-supplier of the canopy pelmets, and the LED pelmet lighting illuminating the fascia.

MAG ASSEMBLY MOVES TO LARGER FABRICATION FACILITY

MAY 20, 2012

MAG Assembly has expanded its manufacturing operations and had moved to a larger and more modern facility near the airport in Auckland. Come in and see our new facilities.

ICONIC SPITTING FEATHERS SIGNAGE WINS SILVER MEDAL FOR NEW ZEALAND SIGNAGE AWARDS

May 1, 2012

May 1, 2012

Sign: SPITTING FEATHERS

Client: Louey Signs

MAG Assembly is the design and construction behind the Louey Signs of

Auckland award winning Spitting Feathers pub sign. The Spitting Feathers

is a classy, modern pub located in Wyndham Street/Wellesley Street in

the heart of Auckland City. The sign was the centre piece for this English

style Pub newly opened to cater for supporters during the Rugby World

Cup 2011.

MAG Assembly’s head designer Nick used his childhood love of Legos to

develop building blocks from 78 individual router-cut sections of 18mm

opal acrylic to eventually end up with a 3 dimensional case. The cats

feathers and even his whiskers which are made from stainless wire all

help to give a perception of depth. Graphics were completed by Loueys

as well as the installation. Illumination was achieved with AXLE Series

White LEDs from AxiomLED/KiwiLED to not only illuminate the faces but

also give a halo effect through a clear mounting plate.

The sign was such a hit with Steve and Wayne, the owners of Louey Signs,

that they decided to enter it into the NZSDA 2012 Sign Awards, where

it won the Silver Medal. It is advantageous to have clever young men

looking at signage challenges in a completely different way.

Needless to say we are very proud of Nick and his clever approaches

to sign manufacture. Maybe he can help you, give him a call!

MAG ASSEMBLY DEVELOPS LARGE BLUM SIGNAGE FOR BRAVE DESIGN

Apr 10, 2012

Apr 10, 2012

Sign: BLUM

Client: Brave Design

Rod and Glen from Brave Design had a brief from their Customer, and

approached us to help design and build a logo for Blum who is a leading

manufacturer of hinges and latches that would be seen from the motorway

some 1.5km away. For such a large sign it was decided that a flexiface

skin would be safest, although this makes for a labour intensive option

the end result speaks for itself. Secondly, a strong illumination was

paramount and to achieve this we used AXLE9-SW65 Axiom LED/Kiwi LEDs.

To compliment the main factory signage an upmarket three sided Pylon

was required for the Company's entrance way, this was illuminated, 2

pack paint finishes, with cut and replace lettering and stainless steel

corner blades.

This, combined with accurate project management and installation by

Brave design, has given Blum signage that not only stands out, but has

many of their neighbors quite jealous.

Thank you Rod and Glen for letting us show off this superb end result.